hotline:020-29026320 |13903018415

-

-

Radiation detection instrumentation

-

HYGP-2223 exposure type X, γ radiation measuring instrument

-

HYGP-2223BX, gamma dose rate meter (with tripod)

-

FI-329M intelligent household nuclear radiation detector

-

HY-2000M digital multi-channel gamma spectrometer

显示更多 -

-

Laboratory Equipment

-

Radioactive distillation apparatus in water

-

2200Q portable turbidity meter

-

SPE Solid Phase Extraction Device

-

Portable spectrophotometer

显示更多 -

-

Portable environmental monitoring equipment

-

VOCs gas analyzer

-

Portable handheld VOC detector

-

Portable all-in-one multi-parameter analyzer

-

Dust detector

显示更多 -

-

Environmental online monitoring system

-

CM-WG8200 grid air quality detection system

-

On-line monitoring system for CM-VOCs-5000 volatile organic compounds

显示更多 -

-

UAV Online Environmental Monitoring

-

OS-2 UAV Electromagnetic Environment Monitoring System

-

Nuclear emergency radioactive source search UAV

-

UAV Monitoring System

显示更多 -

-

On-line Monitoring System of Electromagnetic Radiation

-

On-line Monitoring System of Electromagnetic Radiation

-

Automatic Monitoring System of HYEH460 Electromagnetic Radiation

-

HY-900A launch type radiation environment automatic monitoring station

-

OS-8 S Frequency Selective Electromagnetic Environment Online Monitoring System

显示更多 -

-

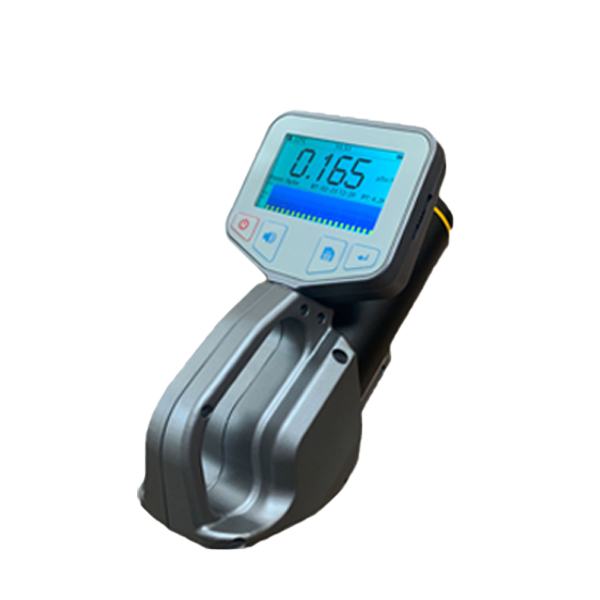

Portable XRF Alloy Analyzer

2024-10-12

Explorer PortableXRF alloy analyzer manufacturer is Tianrui Instrument, which combines 20 years of handheld research and development experience and concentrates a number of technologies such as optoelectronics, microelectronics, semiconductors and computers to develop a new generation of handheld XRF products with independent intellectual property rights. The EXPLORER 5000 handheld XRF alloy analyzer (handheld spectrometer) is a handheld alloy analyzer using a new large-screen high-resolution LCD display and a new digital multi-channel data processor. The ultra-low detection limit makes the performance of the handheld analyzer comparable to that of the desktop; the instrument is small in size, light in weight, and can be carried for measurement, suitable for the analysis of various types of alloy samples.

More convenient operation

2. Light weight, small size, ergonomic handle design, equipped with special instrument cover, easier to grasp, and more convenient to use in the field.

2.270 ° rotatable 5-inch HD screen supports multi-point control and can be clearly displayed under any light.

3, sealed integrated design, with waterproof and dustproof function, can be used continuously in harsh environments.

4. There is no need to prepare samples, and the surface of the test object can be measured directly. The instrument can be hand-held for rapid testing, and can also be used to carry out detailed tests on samples for a long time.

HaveIntelligent alloy library 500 multiple grades

Can accurately detect a variety of precious metal alloys, high and low alloy steel, stainless steel, tool steel, chromium/Molybdenum steel, nickel alloy, cobalt alloy, nickel/cobalt heat-resistant alloy, titanium alloy, copper alloy, bronze, zinc alloy, tungsten alloy, etc., non-destructive testing, 2 seconds to know the composition of the material and the number. It can also quickly identify the light combination number of aluminum and magnesium, and can carry out reliability identification (PMI) and confirmation of materials to control the quality of materials.

Previous Page:

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

online message

Telephone:13903018415(Manager Wang)

Business: 020-29026320

E-mail:wangxueli@haiyoukj.com

Address: Room 703, Tian 'an Innovation Building, Panyu Energy Saving Science Park, 555 Panyu Avenue North, Donghuan Street, Panyu District, Guangzhou

Sweep code attention