hotline:020-29026320 |13903018415

-

-

Radiation detection instrumentation

-

HYGP-2223 exposure type X, γ radiation measuring instrument

-

HYGP-2223BX, gamma dose rate meter (with tripod)

-

FI-329M intelligent household nuclear radiation detector

-

HY-2000M digital multi-channel gamma spectrometer

显示更多 -

-

Laboratory Equipment

-

Radioactive distillation apparatus in water

-

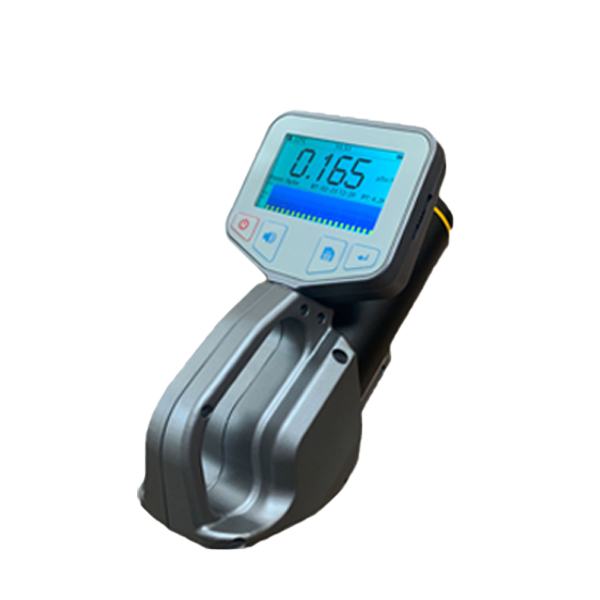

2200Q portable turbidity meter

-

SPE Solid Phase Extraction Device

-

Portable spectrophotometer

显示更多 -

-

Portable environmental monitoring equipment

-

VOCs gas analyzer

-

Portable handheld VOC detector

-

Portable all-in-one multi-parameter analyzer

-

Dust detector

显示更多 -

-

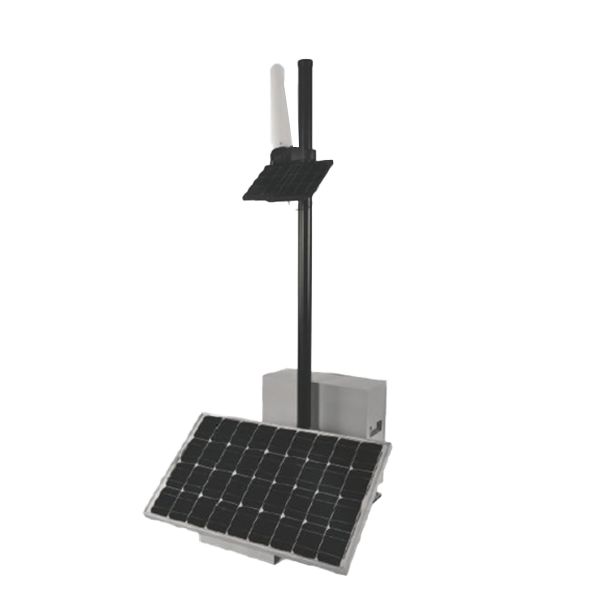

Environmental online monitoring system

-

CM-WG8200 grid air quality detection system

-

On-line monitoring system for CM-VOCs-5000 volatile organic compounds

显示更多 -

-

UAV Online Environmental Monitoring

-

OS-2 UAV Electromagnetic Environment Monitoring System

-

Nuclear emergency radioactive source search UAV

-

UAV Monitoring System

显示更多 -

-

On-line Monitoring System of Electromagnetic Radiation

-

On-line Monitoring System of Electromagnetic Radiation

-

Automatic Monitoring System of HYEH460 Electromagnetic Radiation

-

HY-900A launch type radiation environment automatic monitoring station

-

OS-8 S Frequency Selective Electromagnetic Environment Online Monitoring System

显示更多 -

-

Three key points of laboratory equipment management!

2024-10-12

Laboratory InstrumentsStorage of equipment

Instruments and equipment are very important experimental resources. It is very important to keep this piece of instruments and equipment. Therefore, special personnel must be responsible for it, and the classification of equipment and instruments must be done well. The details include the following seven points:

2. To do a good job in the maintenance of all kinds of instruments, maintenance work, test instruments to special management.

2. The precision instruments should be classified, and each instrument should be calibrated and tested regularly.

3. Make records of the use, movement and verification of various instruments.

4. No instrument may be borrowed without normal procedures.

5. The instrument shall be stored in a standardized manner and kept clean and tidy.

6. Check whether the returned instrument is damaged, report the damage immediately and repair it in time.

7. Laboratory personnel responsible for the daily custody of the instrument.

Maintenance of laboratory instruments and equipment

The daily maintenance of instruments and equipment is a common means to ensure the stability and reliability of instruments and equipment. Especially for large instruments and equipment should pay attention to dust, moisture, mildew, sunscreen. To take appropriate and effective measures to ensure that the instrument is not affected by external factors and damage. For equipment maintenance, mainly the following 5 points:

2. Before using the instrument, the experimenters should be familiar with its performance, principle and operating procedures, and illegal operation is strictly prohibited.

2. Non-experimental personnel shall not use the instrument.

3. In addition to periodic maintenance, laboratory personnel should also check the condition of instruments and equipment from time to time, and timely maintenance should be carried out if abnormal instruments are found.

4. Non-measurement testing or maintenance personnel are not allowed to disassemble and adjust mobile instruments at will.

5. The equipment repaired according to the cycle must be maintained or repaired in time when it is due, and the use time shall not be extended at will.

Instrument and equipmentPeriodic verification

When the product quality equipment is used to a certain period of time, in order to ensure the accuracy and traceability of the product quality inspection instrument, it is necessary to organize the use of the product quality inspection instrument, testing items to make the traceability measurement of each test parameter and uncertainty value assessment or periodic verification to be calibrated.

2. The equipment must develop and record maintenance, verification cycle schedule.

2. All kinds of instruments and equipment must be used only after the laboratory director (technical director) cooperates with the verification personnel to pass the verification, and the qualified mark is pasted on the obvious position of the instrument.

3. Newly purchased instruments and equipment must be checked before warehousing, and instruments with expired inventory must be re-verified before use.

4. All instruments and equipment that are inaccurate or do not have a certificate are prohibited from use.

In short, the management of instruments and equipment is an important part of laboratory work, is a very comprehensive work, but also very detailed and tedious work, only seriously do a good job in the management of product quality inspection instruments and equipment, in order to effectively grasp the normal operation of experimental instruments and equipment.

Previous Page:

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

online message

Telephone:13903018415(Manager Wang)

Business: 020-29026320

E-mail:wangxueli@haiyoukj.com

Address: Room 703, Tian 'an Innovation Building, Panyu Energy Saving Science Park, 555 Panyu Avenue North, Donghuan Street, Panyu District, Guangzhou

Sweep code attention