hotline:020-29026320 |13903018415

-

-

Radiation detection instrumentation

-

HYGP-2223 exposure type X, γ radiation measuring instrument

-

HYGP-2223BX, gamma dose rate meter (with tripod)

-

FI-329M intelligent household nuclear radiation detector

-

HY-2000M digital multi-channel gamma spectrometer

显示更多 -

-

Laboratory Equipment

-

Radioactive distillation apparatus in water

-

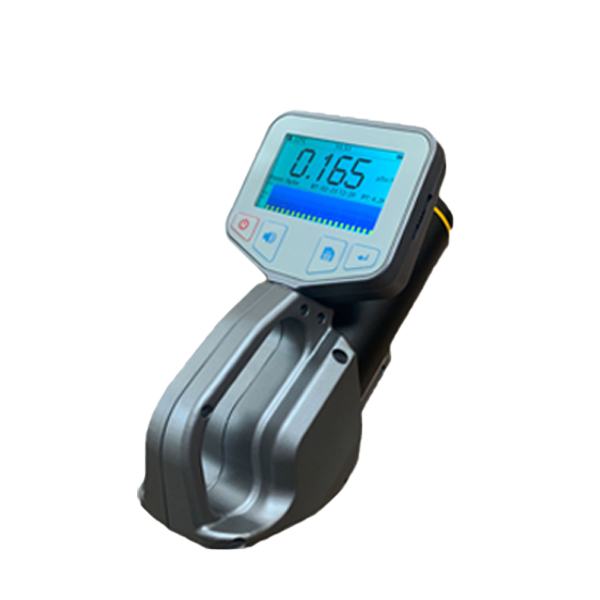

2200Q portable turbidity meter

-

SPE Solid Phase Extraction Device

-

Portable spectrophotometer

显示更多 -

-

Portable environmental monitoring equipment

-

VOCs gas analyzer

-

Portable handheld VOC detector

-

Portable all-in-one multi-parameter analyzer

-

Dust detector

显示更多 -

-

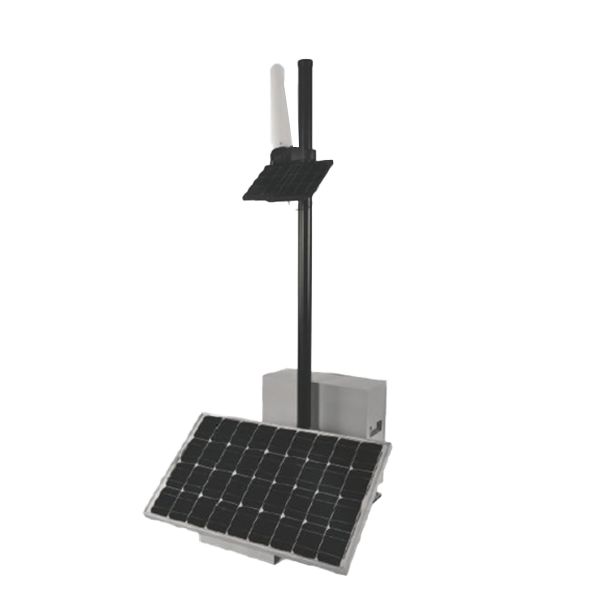

Environmental online monitoring system

-

CM-WG8200 grid air quality detection system

-

On-line monitoring system for CM-VOCs-5000 volatile organic compounds

显示更多 -

-

UAV Online Environmental Monitoring

-

OS-2 UAV Electromagnetic Environment Monitoring System

-

Nuclear emergency radioactive source search UAV

-

UAV Monitoring System

显示更多 -

-

On-line Monitoring System of Electromagnetic Radiation

-

On-line Monitoring System of Electromagnetic Radiation

-

Automatic Monitoring System of HYEH460 Electromagnetic Radiation

-

HY-900A launch type radiation environment automatic monitoring station

-

OS-8 S Frequency Selective Electromagnetic Environment Online Monitoring System

显示更多 -

-

How to Detect Whether Carbon Dioxide and Argon Mixture Meet the Standard

2024-10-12

The role of carbon dioxide and argon gas mixtures

The large amount of spatter generated during industrial welding is due to the use of carbon dioxide gas for shielded welding, and the emergence of argon and carbon dioxide mixed gas (referred to as argon gas) shielded welding solves this problem.

Argon and carbon dioxide mixed gas shielded welding compared to pure carbon dioxide gas shielded welding, to further improve the welding efficiency and welding quality, while reducing a large number of spatter..

First of all, the advantages of argon and carbon dioxide mixture in the welding process

2: Pure carbon dioxide is a gas heavier than air. It has a high thermal conductivity properties, the arc is wide, the weld is also wide. Carbon dioxide has a strong oxidizing property, and it produces a large spatter during welding. Argon is also a gas heavier than air. It is used for welding can effectively protect the droplet and weld pool, improve the smoothness of the welding surface, less spatter, but the argon generated by the ionization arc is narrow, and the arc is unstable. Therefore, these two gases have different advantages and disadvantages when used alone for welding. The mixture of carbon dioxide and argon makes the advantages of the two gases in welding fully utilized, while avoiding their respective disadvantages. The argon component improves the quality of the welding surface and reduces the spatter caused by carbon dioxide gas. The carbon dioxide component enhances the stability of the arc and improves the heat conduction, thereby increasing the mechanical properties of the welding material. The mixture of argon and carbon dioxide is an ideal welding shielding gas.

2: the use of pure carbon dioxide welding is generally not easy to produce excessive injection. Because it makes the welding wire in the welding process of the droplet is larger, in the droplet to get rid of the surface tension down into the welding pool in the process of an upward electromagnetic force, because the droplet is large, so the electromagnetic force is unbalanced on the droplet, so that a large number of droplets in the fall will fall to the outside of the welding pool, it produces a large amount of splash. Argon and carbon dioxide gas mixture can produce excessive jet, it makes the wire droplets become more and more small, when the small droplets fall, the electromagnetic force acting on the droplets is much more balanced than the large droplets. In this way, a large number of small molten droplets will transition to the molten pool, and the generation of spatter will be greatly reduced. The spatter will be reduced, so that the welding workers do not need to stop and clean the welding nozzle frequently, and there is no need to use special workers to clean the spatter on the seam road. The mixed gas welding greatly improves the welding production efficiency. The use of argon and carbon dioxide mixture welding reduces spatter than pure carbon dioxide gas welding.

Detection of Carbon Dioxide and Argon Mixture

Qingdao Haitel HT-BH pump suction carbon dioxide detector has a very clear large liquid crystal display and sound and light alarm prompts. It is an intrinsically safe equipment that can continuously detect the concentration of the measured gas and is suitable for explosion-proof places. The detector is an intrinsically safe product, which meets the general requirements of the national executive standard GB3836.2-2000 and the GB3836.4-2000 intrinsically safe type.

HT-BH pump suction carbon dioxide detector adopts imported intelligent sensor, stable and excellent performance, powerful sound and light alarm, easy to use. The sensor responds quickly to the detected gas and can give you an alarm in time when a hazard occurs. It is a sensitive and alarm detector for detecting gas in today's industrial field. And can adapt to a variety of extreme working environment. Strong explosion-proof flame-retardant shell, light weight, easy to carry, and withstand impact. To ensure that in a very adverse working environment can also detect dangerous gases and prompt the operator to prevent. It is widely used in metallurgy, coal, steel mills, petroleum, chemical industry, papermaking, electric power, medicine, food processing, tunnels, tunnels and other places!

recommend News

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

online message

Telephone:13903018415(Manager Wang)

Business: 020-29026320

E-mail:wangxueli@haiyoukj.com

Address: Room 703, Tian 'an Innovation Building, Panyu Energy Saving Science Park, 555 Panyu Avenue North, Donghuan Street, Panyu District, Guangzhou

Sweep code attention